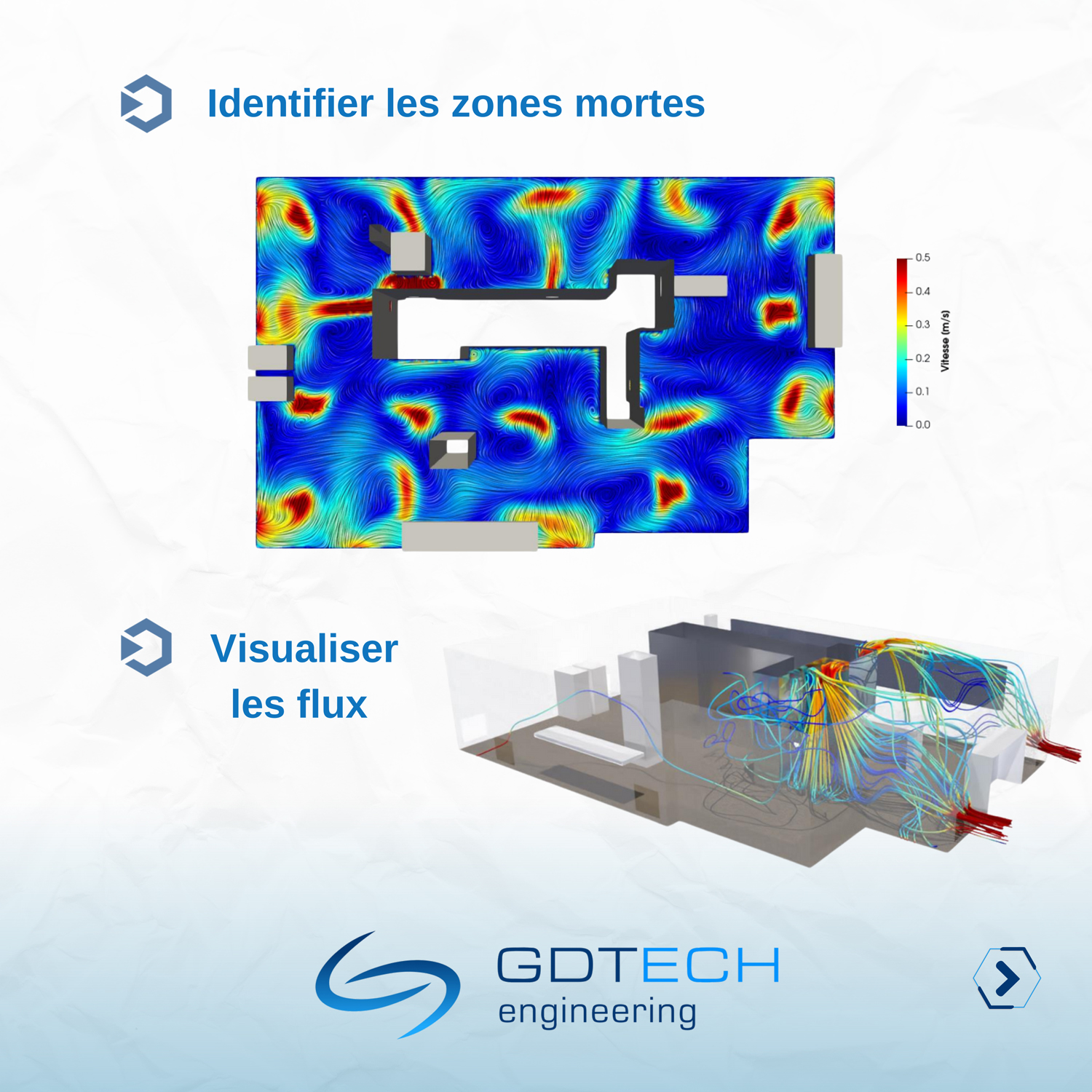

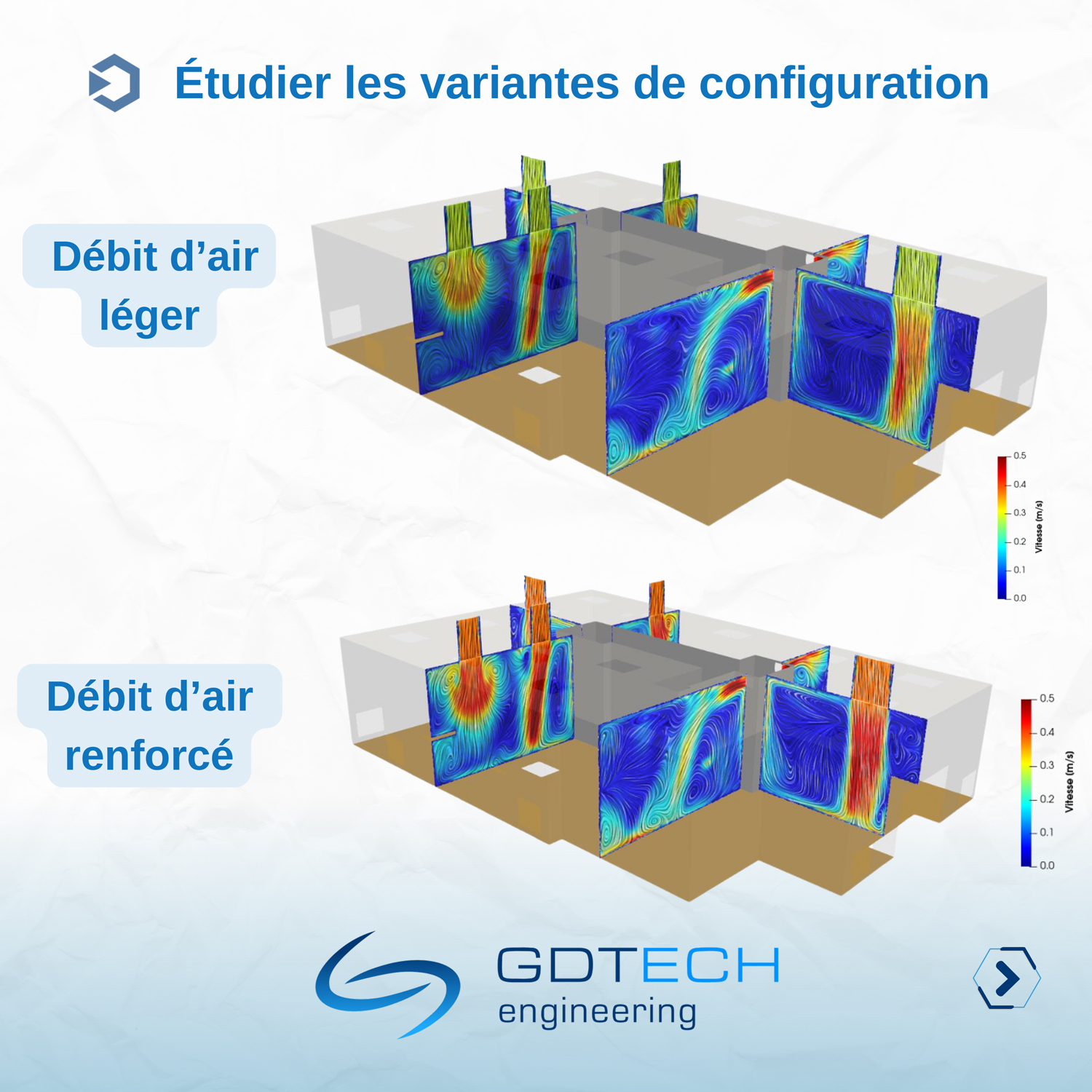

The construction of a controlled atmosphere room (CAR) requires ensuring proper airflow distribution. Numerical simulation (CFD) can be used to optimize ventilation systems, verify their performance prior to manufacturing, and identify potential stagnation zones (dead zones), air velocities, and air flow directions. These simulations are also valuable for anticipating smoke tests performed during facility qualifications.

A few months ago, during the A3PBiarritz international congress, we were asked to perform an airflow simulation for an industrial building intended for a pharmaceutical production plant.

Study Objective

- Analyze the impact of two airflow configurations on internal circulation.

- Identify particle accumulation zones to minimize contamination risks.

- Evaluate air age and contaminant dispersion.

CFD or numerical simulation enables precise prediction of:

- Stagnation zones or “dead zones”

- Optimization of airflows and velocities

- The performance of diffusers and extractors

- Validation of air change rates

- Anticipation of smoke tests before final facility qualification

The future of cleanroom airflow design relies on innovation and precision. Thanks to numerical simulation, we can design increasingly efficient systems that comply with the regulations and requirements of Good Manufacturing Practices (GMP). ????

Thanks to Cédric DESARMENIEN, Project Manager at LAPORTE Euro, for his trust in the realization of this project at A3PBiarritz!